The automated system makes distribution of uniforms easy and efficient, allowing considerable savings in terms of space and optimisation of uniforms in circulation. Good automated management not only makes uniforms available 24 hours a day, but also allows saving on costs and reducing environmental impact, which affects the entire service chain with less washing to be carried out, less energy to be used and less materials to be distributed. In addition, if garments are equipped with RFID-UFT tags, every aspect of the service can be managed, from the washing to the distribution of clean garments, up to the collection of dirty garments.

This allows optimising workflows, minimising dispersions and stocks and optimising purchases.The solution guarantees complete tracking of uniforms, both in “size” mode and “customised” mode, as well as “mixed mode”, i.e. size and customised in the same facility.The system was designed to be easy to use and maintain, it is fully electric and can work with Barcode and RFID, LF, HF, UHF technologies.

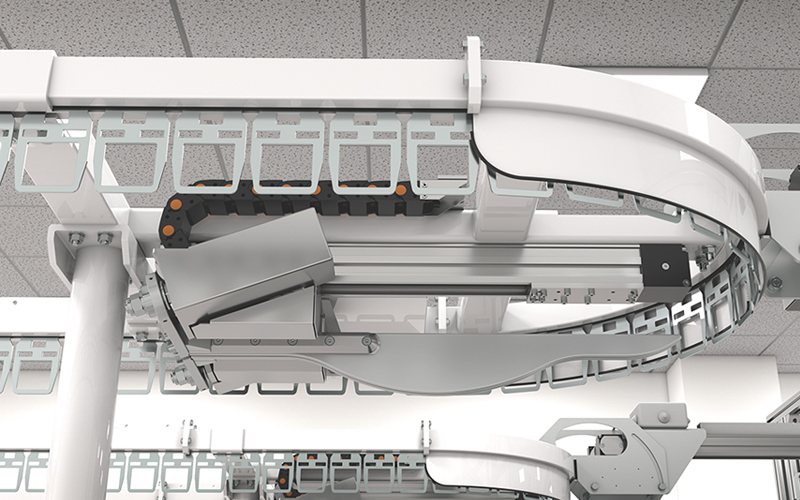

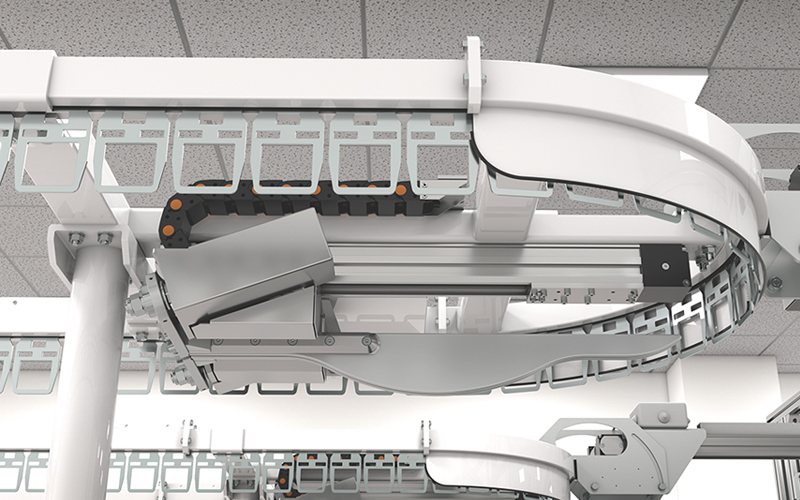

The solution consists of:

• one or more automatic redelivery doors *

• one or more modular conveyor belts *

• one or more modular conveyor belts **

• one or more redelivery doors for used uniforms

* based on the number of users present

** based on the number of belts installed